系统完善 高效可靠

PRODUCTS

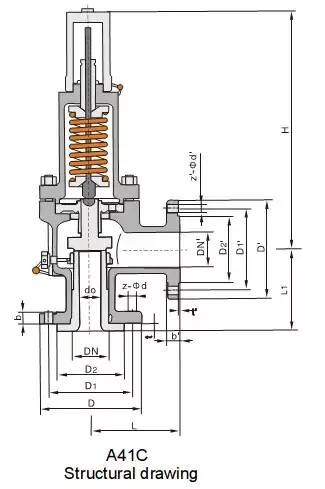

Type A41C Safety Valve

Safety Valves, angle type

Low lift safety valve

Metal to metal seated

Flanged connection acc. to ANSI B16.5

Applications:

Provided as safety device for protection against excessive pressure in pressure vessels.

Approved for gases, vapours and fluids.

Working temperatures:

-60°C up to +200°C for stainless steel material

-29°C up to 300°C for cast steel material

Standards Compliance:

Design and Manufacture: API RP 520

Face to Face(end to end): API 526

Test and Inspection: API 527

Main property specifiecation

| Mormal Pressure | PN | 150 | 300 | 600 | 900 | 150 |

| Body strength | Ps(Mpa) | 3.0 | 7.5 | 15 | 22.5 | 38 |

| Set pressure | Pk(Mpa) | 0.1-2 | 1.6-5 | 3.2-10 | 8-25 | 10-25 |

| Seal pressure | Pm(Mpa) | 90%Pk | ||||

| Reseation pressure | Ph(Mpa) | ≥90%Pk | ||||

| Relieving Pressure | Pp(Mpa) | ≤1.1Pk | ||||

| Lift height | H(mm) | ≥1/20 d0 | ||||

| Appropriate temp. | C (WCB) P, R (SS304, SS316) | ≤300℃ ≤200℃ | ||||

| Appropriate Medium | Air, Oil, Steam, Water, Corrosive medium | |||||

Code of throat diameter

| Code | Diameter | Code | Diameter | |||

| D | 10 | L | 20 | |||

| E | 13 | M | 55 | |||

| F | 16 | N | 60 | |||

| G | 20.5 | P | 72 | |||

| H | 26 | Q | 96 | |||

| J | 33 | R | 115 | |||

| K | 40 | T | 148 | |||

Main Dimensions

| A41C150, A41C150P, A41C150R | |||||||||||||||||

| Nominal Diameter (in) | Dimensions(mm) Inlet flange 150Lb | ||||||||||||||||

| d0 | D | D1 | D2 | b | t | Z-Φd | DN' | D' | D1' | D2' | b | t | Z'-Φd' | L | L1 | H | |

| 1/2" x 1/2" | D | 89 | 60.5 | 35 | 12 | 5 | 4-15 | 15 | 89 | 60.5 | 35 | 12 | 1.6 | 4-15 | 90 | 90 | 260 |

| 3/4" x 1" | D | 98 | 70 | 43 | 14 | 5 | 4-15 | 25 | 108 | 79.5 | 51 | 15 | 1.6 | 4-15 | 96 | 92 | 280 |

| 1" x 1" | D | 108 | 79.5 | 51 | 15 | 5 | 4-15 | 25 | 108 | 79.5 | 51 | 15 | 1.6 | 4-15 | 100 | 100 | 290 |

| 1" x 2" | E | 108 | 19.5 | 51 | 15 | 5 | 4-15 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 115 | 105 | 290 |

| 11/2" x1 1/2" | G | 127 | 98.5 | 73 | 18 | 5 | 4-15 | 40 | 127 | 98.5 | 73 | 18 | 1.6 | 4-15 | 121 | 124 | 330 |

| 11/2" x2" | G | 127 | 98.5 | 73 | 18 | 5 | 4-15 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 121 | 124 | 330 |

| 2" x 3" | J | 152 | 120.5 | 92 | 18 | 5 | 4-19 | 80 | 190 | 152.5 | 127 | 22 | 1.6 | 4-19 | 124 | 136 | 350 |

Remark: 150Lb for outlet flange

| A41C300, A41C300P, A41C300R | |||||||||||||||||

| Nominal Diameter (in) | Dimensions(mm) Inlet flange 300Lb | ||||||||||||||||

| d0 | D | D1 | D2 | b | t | Z-Φd | DN' | D' | D1' | D2' | b | t | Z'-Φd' | L | L1 | H | |

| 1/2" x 1/2" | D | 95 | 66.5 | 35 | 15 | 5 | 4-15 | 15 | 89 | 60.5 | 35 | 12 | 1.6 | 4-15 | 90 | 90 | 260 |

| 3/4" x 1" | D | 117 | 82.5 | 43 | 16 | 5 | 4-19 | 25 | 108 | 79.5 | 51 | 15 | 1.6 | 4-15 | 96 | 92 | 280 |

| 1" x 1" | D | 124 | 89 | 51 | 18 | 5 | 4-19 | 25 | 108 | 79.5 | 51 | 15 | 1.6 | 4-15 | 100 | 100 | 290 |

| 1" x 2" | E | 124 | 89 | 51 | 18 | 5 | 4-19 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 115 | 105 | 290 |

| 11/2" x1 1/2" | G | 156 | 114.5 | 73 | 20 | 5 | 4-22 | 40 | 127 | 98.5 | 73 | 18 | 1.6 | 4-15 | 121 | 124 | 330 |

| 11/2" x2" | G | 156 | 114.5 | 73 | 20 | 5 | 4-22 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 121 | 124 | 330 |

| 2" x 3" | J | 165 | 127 | 92 | 23 | 5 | 8-19 | 80 | 190 | 152.5 | 127 | 22 | 1.6 | 4-19 | 124 | 136 | 350 |

Remark: 150Lb for outlet flange

| A41C600, A41C600P, A41C600R | |||||||||||||||||

| Nominal Diameter (in) | Dimensions(mm) Inlet flange 600Lb | ||||||||||||||||

| d0 | D | D1 | D2 | b | t | Z-Φd | DN' | D' | D1' | D2' | b | t | Z'-Φd' | L | L1 | H | |

| 3/4" x 1" | D | 118 | 82.5 | 43 | 16 | 7 | 4-15 | 25 | 108 | 79.5 | 51 | 15 | 1.6 | 4-15 | 105 | 110 | 280 |

| 1" x 2" | D | 124 | 89 | 51 | 20 | 7 | 4-19 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 115 | 105 | 290 |

| 11/2" x1 1/2" | F | 156 | 114.5 | 73 | 22 | 7 | 4-22 | 40 | 127 | 98.5 | 73 | 18 | 1.6 | 4-15 | 147 | 162 | 330 |

| 11/2" x2" | F | 156 | 114.5 | 73 | 22 | 7 | 4-22 | 50 | 152 | 120.5 | 92 | 18 | 1.6 | 4-19 | 147 | 162 | 330 |

Remark: 150Lb for outlet flange

| A41C900, A41C900P, A41C900R | |||||||||||||||||

| Nominal Diameter (in) | Dimensions(mm) Inlet flange 900Lb | ||||||||||||||||

| d0 | D | D1 | D2 | b | t | Z-Φd | DN' | D' | D1' | D2' | b | t | Z'-Φd' | L | L1 | H | |

| 1" x 11/2" | d0 | 150 | 101.6 | 51 | 28 | 7 | 4-25 | 40 | 156 | 114.5 | 73 | 20 | 1.6 | 4-22 | 125 | 125 | 320 |

| 11/2" x1 1/2" | F | 178 | 123.8 | 73 | 32 | 7 | 4-29 | 40 | 156 | 114.5 | 73 | 20 | 1.6 | 4-22 | 150 | 195 | 350 |

Remark: 300Lb for outlet flange

Materials for main parts

| NO | Name of part | Materials A41H-C | Materials A41Y-P | Materials A41Y-R |

| 1 | Body | WCB | 304 | 316 |

| 2 | Nozzle | 2Cr13/ 304 | 304 | 316 |

| 3 | Adjusting Ring | 2Cr13/ 304 | 304 | 316 |

| 4 | Disc | 2Cr13/ 304 | 304 | 316 |

| 5 | Guide sleeve | 2Cr13/ 304 | 304 | 316 |

| 6 | Bonnet | ZG230-450 | ZG230-450 | ZG230-450 |

| 7 | Spring | 50CrVA | 50CrVA coated teflon | 50CrVA coated teflon |

| 8 | Stem | 2Cr13 | 304 | 316 |

| 9 | Adjusting bolt | 45 | 2Cr13 | 2Cr13 |

| 10 | Cap | ZG200-400 | ZG200-400 | ZG200-400 |

| Sealing surface of material "H" depositing D507, "Y" depositing stellite | ||||

Essential:

Valves are delivered at a set pressure, therefore when ordering

Please confirm set pressure, medium and temperature

TS

Safety accessory and Safety protection device

Manufacture License of Special Equipment, People's republic of China

Closed bonnet with Cap, Low Lift